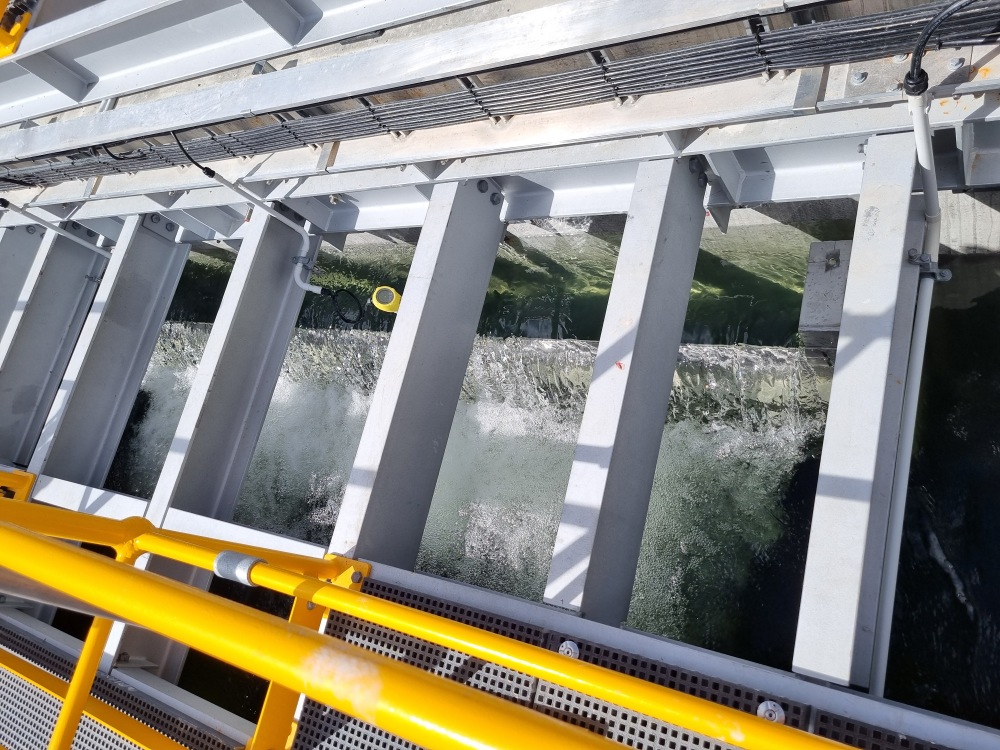

A water treatment plant in the greater Wellington Region required an upgrade to increase capacity to 140 ML/d, improve redundancy and resilience, and continue to meet the requirements of the Drinking-Water Quality Assurance Rules. This was achieved through the installation of a new Dissolved Air Floatation (DAF) system and increasing the capacity of the existing chemical dosing and solids-handling systems in cooperation with Wellington Water’s in-house automation engineers.

The increased capacity and dosing are now in operation, providing clean water to the region as planned.

WWTMDAF_3

WWTMDAF_2

WWTMDAF_4

WWTMDAF_5

Services provided

- Functional design of PACl, Polymer and PAC storage and dosing

- PLC and SCADA development, factory and site acceptance testing

- Commissioning for the full DAF plant

Product description

- Rockwell L84E ControlLogix PLC

- Updates to existing Citect SCADA